Manufacturing Assembly Fixtures

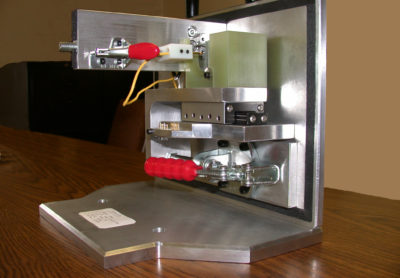

All fixtures are constructed with precision machined components for consistent repeatability and accurate product assembly. Our unique MILL-PLANER machining equipment is capable of ±.0025″ accuracy over a 142″ travel for extraordinarily large requirements with drilled holes, end milled clean flat surfaces and similar detailing of highly accurate fixturing. Some examples of our work are a electromechanical ordnance detonator centrifugal force test fixture, A electrical continuity test fixture for a defense contractor’s missile casing electrical contact requirement and a assembly fixture to align a laser detector with a missile nose casing.

Contact Us for your next Manufacturing Assembly Fixtures need.

Call Now:

800.836.7614

NOSE ASSEMBLY FIXTURE FOR DEFENSE CONTRACTOR

ELECTROMECHANICAL ORDNANCE TEST FIXTURE

ALIGNMENT FIXTURE FOR DRILLING STATION