We make stainless steel piping systems used to transfer chocolate from melting and tempering tanks to the process equipment in our customer’s facilities. Our stainless steel pipe is either single wall straight pipe or dual layer water jacketed pipe depending on length of travel and temperature conditions of the application. Each section of pipe has sanitary fittings welded onto both ends of the pipe. In many cases insulation and an electric external heat source covers the straight pipe to maintain the proper transfer temperature. For the water jacketed pipe heated water is circulated through the outer layer of the dual pipe to keep the chocolate warm.

Our most common application is providing water jacketed piping as part of our automated chocolate belt coater system. These systems use a use a variable speed chocolate pump to move the chocolate from the tank to the belt coater and back to the chocolate tank during the off portions of the coating cycle. The belt coater includes a self contained heating system with an adjustable immersion heater and a circulating pump to move the water through the jacketed pipe. Each section of pipe is connected with flex hose which is also wrapped around any elbows or flanges so they don’t cool the chocolate.

For instances where supplying heated water to a jacketed pipe is not practical, we also make straight single wall piping systems. These systems will use a combination of heating cable and insulation instead of heated water to maintain the product temperature. These are typically used to distribute chocolate longer distances throughout the facility including to multiple locations or machines.

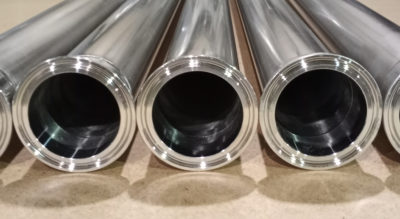

STAINLESS STEEL WATER JACKETED PIPE

STAINLESS STEEL PIPE WITH SANITARY FITTINGS